Transform Your Hydrogen Operations

Stay competitive in the green energy revolution by adopting advanced digital solutions. Modernize processes, optimize production, and lead in sustainable energy with scalable digital transformation.

Revolutionizing Hydrogen Production:

Are You Prepared for the Digital Era?

As the hydrogen industry evolves, producers face pressure to scale operations, enhance efficiency, and ensure sustainability. Embracing digital transformation is no longer optional but essential. Companies must leverage advanced technologies to stay ahead of the curve and address the following critical challenges:

Enhancing Operational Efficiency

In a highly competitive market, hydrogen producers need to streamline operations and automate manual processes to keep up with market demands and reduce costs. The move from manual to automated processes can significantly increase productivity and reduce human error.

Improving Data Integration and Accessibility

Seamless data flow across all departments is crucial for maintaining up-to-date information and making informed decisions. Digital solutions enable real-time monitoring and management of production processes, ensuring data accuracy and availability.

Scaling Production Capabilities

With the global demand for green hydrogen projected to grow exponentially, scaling production capacities quickly and efficiently is paramount. Digital tools can help optimize production lines and predict potential issues before they impact operations.

Ensuring Regulatory Compliance and Safety

Meeting safety standards and regulatory requirements is essential for sustainable operations and market acceptance. Advanced digital solutions help in tracking compliance and maintaining high safety standards, minimizing risks associated with hydrogen production.

Nel Hydrogen Transforms Operations with CLEVR

"I think we build tomorrow together in different ways. We try to build the future by providing equipment to produce green hydrogen to enable the green transition, and CLEVR with the information technology will help us do that efficiently."

Torsten Mann

Products and Engineering Director, Nel Hydrogen

Design and Prototyping

Experience shorter product design cycles with an advanced CAD system that supports virtual prototyping in both 2D and 3D environments tailored for hydrogen technology. This system integrates key processes such as robotics, 3D printing, and quality inspection operations. The NX integrated design and manufacturing capabilities provide a robust platform for efficient hydrogen product development.

Engineering and Data Management

Teamcenter streamlines the process from design to field testing in the hydrogen sector, enhancing collaboration, improving product quality, and speeding up time-to-market. Coordinating engineering efforts with other departments and leveraging technologies like digital twins and simulation can significantly reduce product development errors.

Collaboration and Workflows

Empower your teams with PLM to make informed decisions and ensure seamless data flow across the hydrogen industry. Features include a business process modeler, change management tools, and an interactive dashboard designed to fuel innovation and boost organizational efficiency to deploy green hydrogen.

Optimized Production

Benefit from real-time monitoring of hydrogen production on both the shop floor and top floor, automated quality checks, and seamless ERP/MES integration. Optimize operations with Opcenter’s analytics and reporting tools, ensuring regulatory compliance and sustainability in green hydrogen manufacturing.

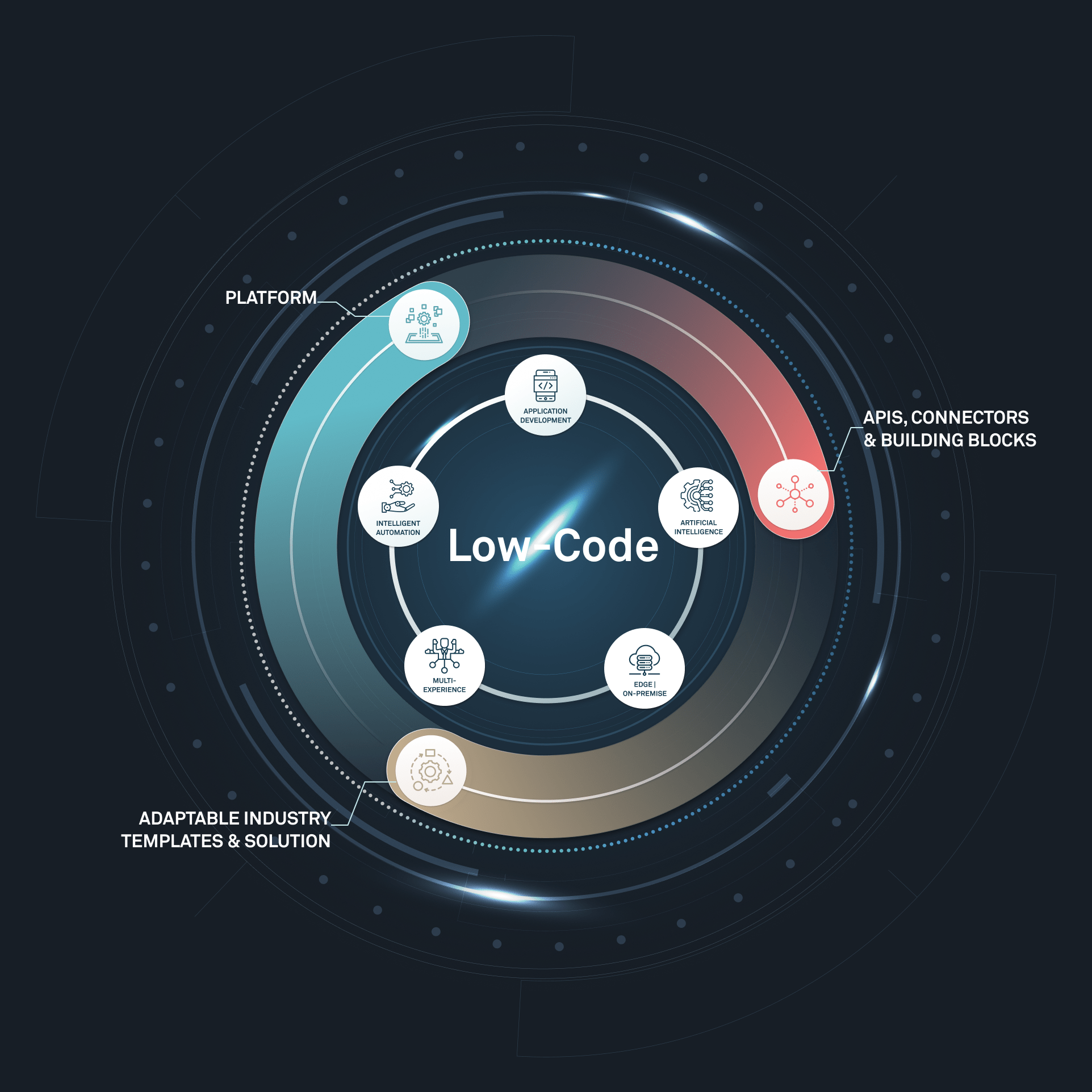

Extending PLM Capabilities with Low-Code Technology

In the hydrogen sector, digital transformation is crucial for enhancing efficiency, agility, and innovation.

Low-code platforms play a strategic role in this transformation by enabling manufacturers to rapidly develop and deploy applications tailored to their unique processes and requirements.

These platforms facilitate the integration of IoT devices, automation of workflows, and real-time data analytics, driving smarter decision-making and operational improvements

Learn moreEmpowering Hydrogen Manufacturers with Business Consultancy and MOM

Manufacturing Operations Management

Manufacturing Operations Management (MOM) elevates Product Lifecycle Management by synchronizing shop floor activities with overarching business strategy. MES monitors real-time data on production orders, material usage, quality metrics, and inventory levels, leading to enhanced efficiency and better decision-making.

Business Consultancy

Business consultancy employs advanced methodologies to enhance efficiency and streamline processes. Supported by strategic sessions between CLEVR and customers, this approach delivers tailored roadmaps and solutions based on the specific needs of each client. The result is refined product development, reduced costs, and improved overall operational efficiency.

Explore Success Stories and Insights for Effective Manufacturing Optimization in the Hydrogen Industry

"Productivity has increased dramatically since we moved production to the Heroya Facility, scaling it up by 10x and achieving a capacity of 500 MW. We transitioned from completely manual processes to a fully automated production line, marking a world first."

Torsten Mann

Products and Engineering Director, Nel Hydrogen

.png?width=500&name=MicrosoftTeams-image%20(90).png)