What is it?

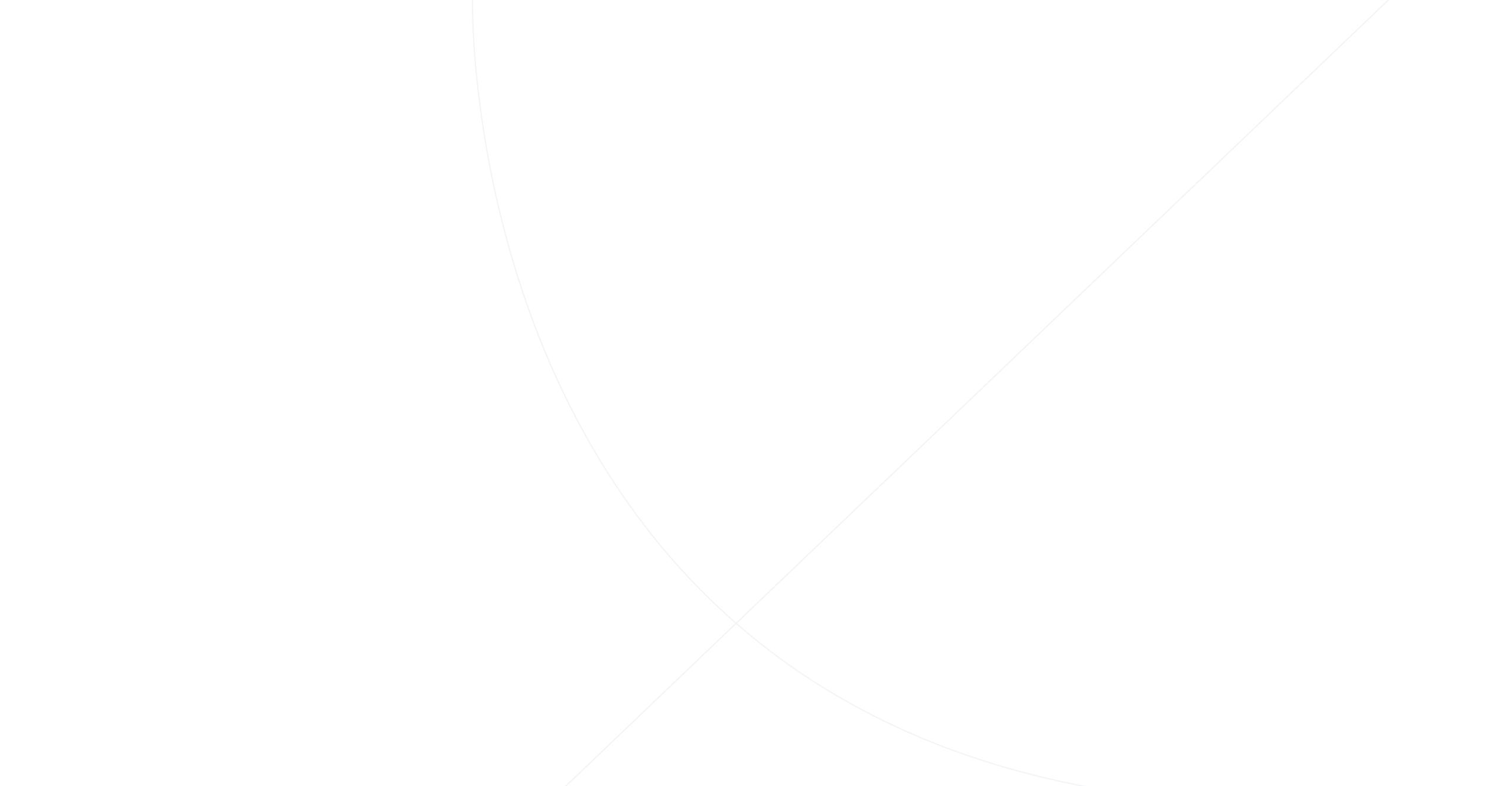

Think of the many different design disciplines involved from early planning to fabrication. Usually, this requires several systems. That’s several information silos lacking data consistency. That means design changes are difficult to manage. Words like ‘costly, time-consuming, frustrating, waste, errors, and vulnerable’ spring to mind. None of which helps in staying competitive and designing the energy-efficient ships of the future. Holistic Ship Design (HSD) solves those problems.

Harmonize your ship design process

Now, imagine there is one system where once there were several. An invisible conductor leading your design and engineering orchestra. Keeping everyone in tune with constantly updated data, a single source of truth. A digital thread, or backbone, of your entire product design and production process. The central source for all documents and information, syncing non-technical and technical teams. A Product Lifecycle Management (PLM) system that securely interfaces with external systems and gives you:

The right data at the right time.

Control and traceability.

A managed environment.

Discover all the possibilities

Optimize design with Digital Twins

HSD means using a 3D Digital Twin and embracing simulation-led design. Parametric modelling, boundary representation (BREP), and product manufacturing information (PMI) allow for optimizing design options quickly as projects progress. PMI can be relayed to automated production equipment (e.g., cutting machines) to facilitate greater automation. Capturing knowledge and creating templates and libraries can speed up the design process. To facilitate this, PLM for Marine relays information from office programs to Computer-Aided Design, Computer-Aided Manufacturing, and Computer-Aided Engineering (CAD/CAM/CAE) programs. It is device, geography, and discipline agnostic. With a complete Digital Twin, you can:

- Better manage your Bill of Materials.

- Enable cross-discipline design.

- Improve predictability – from feasibility to costs and risks.

- Make automation easier.

That’s the method and benefits covered. Now, let’s look at the tools that make HSD a reality for shipyards around the world.

Accelerate ship design with NX CAD

There are many CAD systems, but few offer the same capabilities across multiple product disciplines. NX is the rare design tool that does. And it does so while seamlessly integrating into the PLM backbone, connecting processes. NX offers:

- Parametric modelling for continuous design updates, and lots of flexibility.

- Smooth integration with other systems.

- NX allows for the capture of knowledge without the user having to do any programming.

- CAD users can build a library of tools or parts that can be re-used and customized.

NX is an industry-leading product design solution. It is an end-to-end system that makes it easier to review and validate your designs.

Innovate ship design with Star CCM+

Computational Fluid Dynamics (CFD) modelling simulates and predicts the behaviour of fluids. For example, how water interacts with a ship’s hull. Star-CCM+ connects CFD to the entire PLM backbone. Using design data to automate CFD simulations with the power of the SHERPA algorithm. Star-CCM+ is the pinnacle of what is technically possible. Allowing for automated parameter-driven simulations. This helps to fill in the complete design picture. As such, Marine CFD compliments and can also substitute for several tests, such as towing-tank tests. Star-CCM+ is industry-leading, it is used by classification societies like the Lloyds Register and the American Bureau of Shipping. In fact, most America’s Cup teams use Star-CCM+ to optimize their racing yachts. With Star-CCM+ you can:

- Improve designs to achieve greater efficiency.

- Conduct complex simulations.

- Innovate to meet customer and regulatory demands.

Star-CCM+ allows designers to explore many more design variations and scenarios. This deep research helps to optimize the design. Advancing ship design means improving efficiency, and meeting ever more stringent regulatory requirements, and customer demands.

Optimize your process and your product

CLEVR combines software expertise with marine industry knowledge.

-

Our Marine team is staffed by naval architects that are experts in Holistic Ship Design.

-

We are also experts in industry-leading Siemens technology that allows shipyards to dream big, collaborate across the globe, and build and deliver complex vessels.

-

CLEVR marries the functionality of technology – like Teamcenter, NX, Star-CCM+ and so on – to your business strategy. We use a value lens to do so.

Optimize your design processes to optimize your product. That’s CLEVR.

Interesting resources

Find out how we help our customers in 'engineering-to-order', marine, heavy machinery and manufacturing connect people, processes and systems to automate the design-to-manufacturing value chain.

.jpg?width=500&name=CLEVR%20-%20Websiteheader%20-%201600x900%20%231%20%E2%80%93%201%20(2).jpg)

Connect with us for a personal demo of our PLM for Marine solution. And ask for a free evaluation of your existing system.

.jpg?width=500&name=CLEVR%20-%20Websiteheader%20-%201600x900%20%231%20%E2%80%93%201%20(4).jpg)

Is your ship design process ready to meet the new ecological and economical requirements? Learn about the latest innovations in holistic ship design.